Metal Masts

The IFA had allowed the use of aluminium for spars in 1969. In the beginning, the stiff aluminium was used only for the booms, but not for the masts. Of importance for the technical development of the Finn were the 1972 Olympics in Kiel . The organisers prime aim was to provide boats as uniform as possible. Wooden hulls and wooden masts at this time, though still more successful than GRP hulls and aluminium spars, would not have been as uniform as the newer materials. In order to give equal chances to all competitors, it was decided to use GRP hulls made by Mader and aluminium spars made by Needlespar. North provided the sails.

Thus the 1972 Olympics were the basis of what the Finn class used widely for the next 20 years. The masts made by Needlespar turned out to be all equal - all equally too stiff. In the following years David Hunt turned out his M mast, which was better than the Olympia masts but still too stiff sideways. Later came the Delta, a triangular design. Both disappeared from the scene. Successful only was the Needlespar M. From the engineering point of view the Needlespar masts were crude and mediaeval. |

|

|

|

Four, later three tubes were glued together with an internal tube at the joints and should not have been a match for the ingenious aluminium masts by Bruder and Raudaschl made from one piece. But theory is not always the same as practice. In reality it proved to be prohibitively difficult to produce an aluminium spar with the changing cross section desired in one piece of uniform structure. The different cylindrical and conical parts of a Needlespar mast could be produced in the desired length and quality, carefully selected and finally joined to make a successful unity.

|

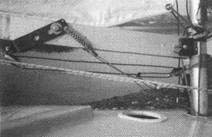

Typical control line system on a Vanguard

|

|

|

|

Later, Needlespar produced many models of the 3M mast. Each mast was distinguished by its tip colours. The general guidelines were red top for stiff masts, blue tops for soft masts and black tops for average bends. There were many more colours however. The way to find a mast in the right 'ball park' was to measure the height of the first join in the mast. The higher this join, the stiffer the mast was. Good masts were between 3750 and 3780 mm measured from the heel to the join. |

|

Centreboard controls, with struts to support case

|

Lever type kicker arrangement |

|

|

Finn Development in America

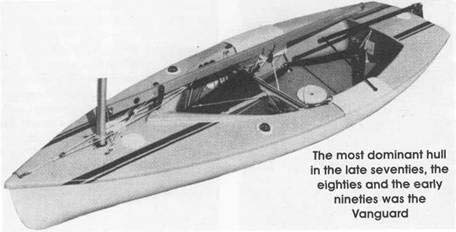

In the early sixties, Fred Miller had developed the Wesco Finn for which he claimed outstanding performance. Originally there was the Newport GRP hull. Teel produced a very stiff durable hull of the highest quality. The Harken brothers took over the know-how of Teel and built and constantly improved their Vanguard boats. In 1976 they provided the know-how for the Abbott Finns of the Olympics in Kingston , and in 1980 for the Soviet builder of the Finns used in Tallinn . In 1984 and in 1992 they provided themselves the boats for the Olympics in Long Beach and Barcelona . Because of this constant input the technology of Vanguard was the highest at that time. This investment must yield a proper return and therefore the Vanguards were also the most expensive boats.

Development

The tendency was clearly towards a boat with a double bottom, which sails as dry as possible. The German Mader and Rein boats were good examples. Here an experiment of the then president of the German Finn Association Peter Kern, has to be mentioned. He got permission from the Technical Committee of the IFA to build and race an experimental Finn with a double bottom above the waterline, thus with a self bailing cockpit. The boat contravened the rale about the height of the floorboards. The cockpit was connected with the transom and all water coming over or remaining in the boat after capsizing drained readily out without bailers. The real difficulty was tacking and mainly gybing because of the reduced height between the floor and the boom. Thus Kern gave up on that idea.

A second trend is to have no water in the bow section after a capsize. This is one of the weakest points in the Vanguard concept. In theory there is never any water in the Vanguard boats either even after turtling her over, but in reality this happens, especially in huge waves. Once you have water in the bow, you could never get her empty without outside help.

|

|

Technically the best solution was provided by the Vlieger Finn. It has a narrow slot of about 20 cm width leading from the cockpit to tile mast step which houses all the control lines. Thus the Vlieger Finn has a huge volume perfectly sealed in the front section. The problem with the Vlieger Finn is that Mark Neeleman, who promoted that boat for a while, switched back to his collection of soft Lanaverres in order to qualify for the 1984 Olympics and then sailed a Vanguard in order to get accustomed to that boat. Could it be that the Vliegers were too stiff because of their construction?

|

|

Some Vanguard sailors sealed off the bow section of their boats completely and ran their control lines on deck. The mast may have a rubber collar. This provides a very dry and light bow under all circumstances. Alternatively some sailors fitted a non-return flap at the front of the centreboard case to stop water flowing forwards, but allowing it aft. |

|